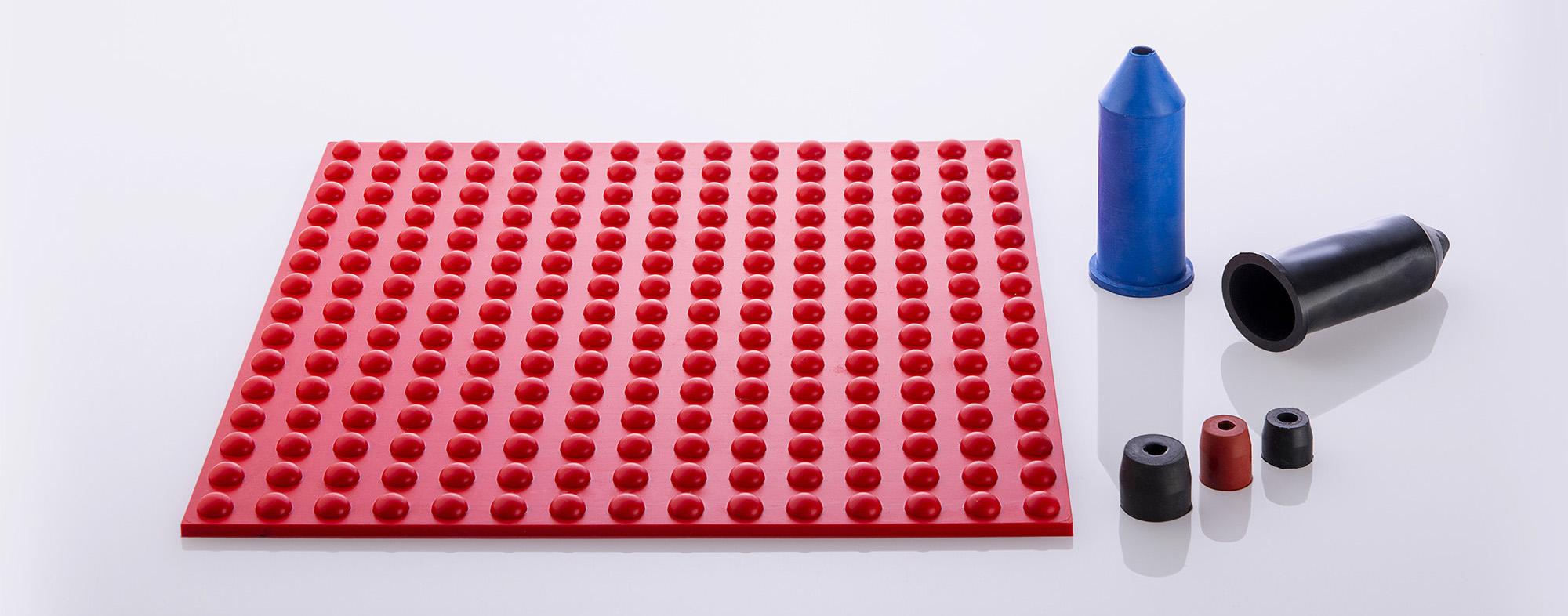

Rubber molding

processing with injection or compression molding of rubber and silicon. Compared to the shearing or die cutting processes, molding also allows to obtain shapes different from classic flat gaskets, with the possibility to provide WRAS, KTW, NW270, NSF61 or other product certifications. The production of printed rubber items requires special molds that are created based on a drawing or on the client’s specifications.

3D Printing

Vergomma is equipped with two 3D printers...